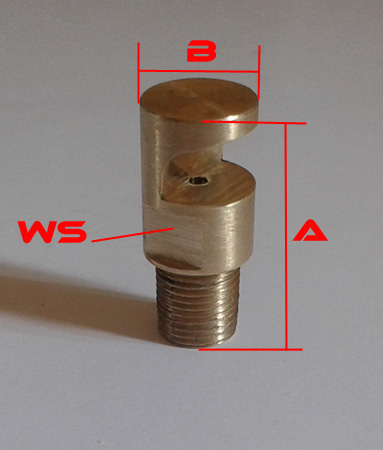

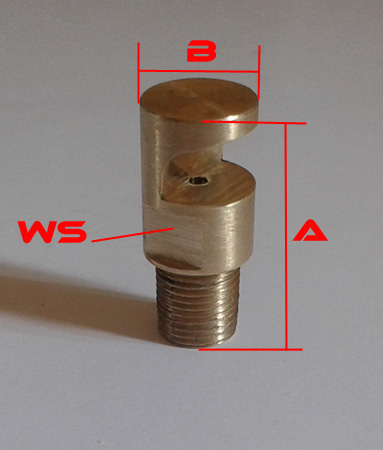

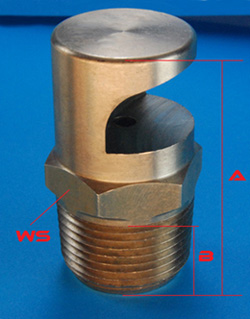

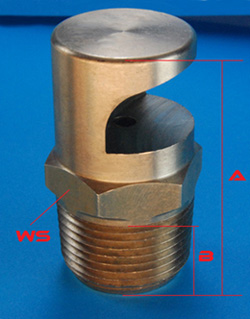

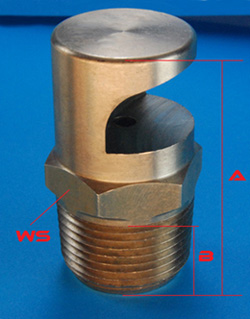

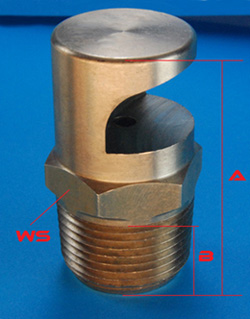

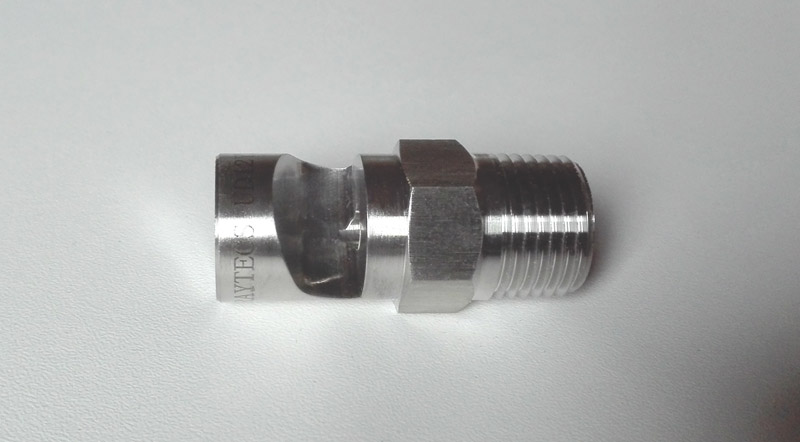

Versions with 130° and 180° spray angles are shown above.

The flat jet nozzles wide-angle spray of the UD series operate according to the principle of deflection

When the liquid passes through the nozzle, and then through the central hole of conveyance, hits the surface deflection suitably inclined and is projected to the outside forming a flat spray.

The distribution has a tapered shape with origin from the center of the nozzle orifice. The deflection surface used allows the formation of very large spray angles, in comparison with similar flat jet nozzles from other manufacturers.

The circular shape of the orifice and the output of the internal structure minimize the risk of clogging in the majority of installations.

These nozzles are ideal in processes that require a wide angle of coverage as in the field of fire-fighting, to isolate, clean and cool vertically areas of interest, or when used in the process of washing of food, gravel and bulk materials placed on a conveyor belt.

They are available also in the 180° spray angle version.

Check with SPRAYTECS for critical dimension, pressure, capacity, fluids in your applications, in order to receive support in your decision.

Nozzle materials must meet correctly chemical composition of fluids in your processes, always remember it.

Spray angle performance varies with pressure. Contact SPRAYTECS for specific data on your critical applications.

The picture on the left shows the spray pattern of these nozzles.